Detroit Diesel Series 60 Jake Brake Torque Specs

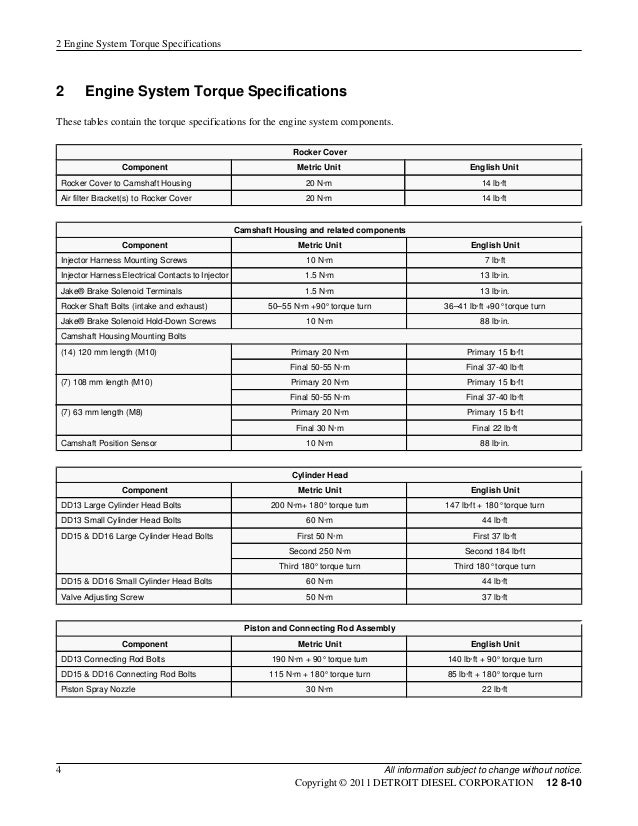

Detroit Diesel Series 60 Cylinder Head Bolts Prior to 2002 torque = 250 - 285 Nm, 184 - 210 lb.ft After 2002 torque = 298 Nm, 220 lb.ft. Detroit Diesel Series 60 Cylinder Head Bolts Prior to 2002 torque = 250 - 285 Nm, 184 - 210 lb.ft After 2002 torque = 298 Nm, 220 lb.ft.

- Detroit Diesel Series 60 Jake Brake Torque Specs 2017

- Detroit Diesel Series 60 Jake Brake Torque Specs List

- Detroit Diesel Series 60 Jake Brake Torque Specs 2004 Dodge Ram 1500

Section 1.28

Camshaft and Camshaft Bearing

The Series 60 camshaft is located on top of the cylinder head, just below the valve cover. The camshaft actuates the intake and exhaust valves and injector operating mechanism. See Figure 'Camshaft and Related Parts' .

Figure 1. Camshaft and Related Parts

Note: The Series 60G camshaft has no injector lobe on the cam.

The camshaft is supported by seven bearing assemblies, consisting of precision-type, replaceable bearing shell inserts that are split at their center lines. Current non-tin-plated production bearing shells are identified by their shiny aluminum color. Current tin-plated service bearing shells have a dull gray sheen. The lower bearing shell is positioned in a saddle that is integral with the cylinder head. The upper bearing shell is held in place by a machined camshaft cap. Upper and lower bearing shells are identical and have locating tangs and oil holes. Only the upper bearing shell oil holes index with oil supply holes in the camshaft caps. See Figure 'Camshaft and Related Parts' . These camshaft caps are precision line-bored after assembly to the cylinder head. Caps are NOT interchangeable once the head is finished. Caps are numbered and must NOT be interchanged with other caps of the same part number from stock or from a different cylinder head.

1. Dowel | 6. Stud, Camshaft Cap (2) |

2. Bearing Shells | 7. Camshaft Cap |

3. Bolt, Camshaft Cover | 8. Camshaft |

4. Rear, Camshaft Access Cover | 9. O-ring |

5. Bolt, Camshaft Cap (13) | 10. Cylinder Head |

Figure 2. Camshaft and Related Parts

The No. 4 camshaft cap is secured to the cylinder head with three bolts; cap numbers 2, 3, 5, and 6 use two bolts each. Caps one and seven have a stud and one bolt each. The stud and nut arrangement on the end caps (1 and 7) allows rocker arm shaft removal without disturbing the gasket eliminator seal from the end camshaft caps to the cylinder head. There are four different camshaft cap configurations. Only the intermediate caps No. 2, 3, 5, and 6 are identical but must not be interchanged during re-assembly. See Figure 'Camshaft Bolt and Cap Location' .

1. Camshaft Cap Bolt (13) | 2. Camshaft Cap Stud and Nut (2) |

Figure 3. Camshaft Bolt and Cap Location

The camshaft is driven by a camshaft drive gear, located in the gear case at the front of the engine and is driven, through a series of intermediate gears, by the crankshaft timing gear. Refer to '1.24.2.1 Check Engine Timing' for gear train information and camshaft drive gear lash measurement and adjustment procedures. See Figure 'Engine Gear Train' .

Figure 4. Engine Gear Train

The camshaft drive gear is indexed to the camshaft drive gear hub by a Woodruff key and retained by a bolt which goes through the camshaft drive gear and hub and threads into the end of the camshaft. The camshaft has a dowel which indexes and fits into the mating hole in the camshaft hub. See Figure 'Cross-Section of Camshaft Drive Gear and Related Parts' .

1. Woodruff Key | 5. Seal Groove |

2. Camshaft Drive Gear Hub | 6. Camshaft Dowel Hole |

3. Camshaft Drive Gear | 7. Camshaft Thrust Plate |

4. O-ring Groove | |

Figure 5. Cross-Section of Camshaft Drive Gear and Related Parts

The camshaft hub is located in the camshaft thrust plate, which is positioned in an opening in the gear case housing. See Figure 'Camshaft Thrust Plate and Related Parts' .

1. Bolt, Thrust Plate Retaining (2) or (3) | 6. Gear Case |

2. Bolt, Camshaft Hub Retaining | 7. Seal, Thrust Plate |

3. Drive Gear, Camshaft | 8. Camshaft |

4. Thrust Plate, Camshaft | 9. Key |

5. O-ring | 10. Hub |

Figure 6. Camshaft Thrust Plate and Related Parts

Access openings are provided in the gear case cover for camshaft drive gear lash adjustment and camshaft retaining bolt removal. See Figure 'Camshaft Drive Gear Access Cover and Adjustable Idler Gear Access' .

Figure 7. Camshaft Drive Gear Access Cover and Adjustable Idler Gear Access

A cover is provided at the rear end of the camshaft and is secured to the No. 7 camshaft bearing cap and the cylinder head by three bolts.See Figure 'Rear Camshaft Access Cover' .

Figure 8. Rear Camshaft Access Cover

Vertical oil passages at the front and rear of the cylinder head deliver oil from the cylinder block front and rear oil galleries to the No. 1 and 7 lower camshaft bearing saddles. From there, the oil is directed up ward ( through the enlarged stud hole) to the No. 1 and 7 upper bearing caps. A drilled passage in each of these caps exits at the rocker arm shaft seat area, where it indexes with a hole in each rocker arm shaft. The rocker arm shafts have internal oil passages that deliver oil to the rocker arm bushings and intermediate upper camshaft bearings. Some of the oil supplied to the rocker arm bushing passes through the oil hole in the bushing to the rocker arm. The rocker is drilled to supply oil to the camshaft follower, roller pin, and bushing. The rocker is also drilled to supply oil to the valve adjusting screw, valve button, retainer clip, intake, and exhaust valve stems and the fuel injector follower. The No. 4 camshaft cap is “Y” drilled, forming an oil path connection between the front and rear rocker arm shafts, to ensure complete lubrication. See Figure 'Cylinder Head Lubrication Schematic' .

1. Rocker Arm, Exhaust Valve | 4. Rocker Arm Shaft |

2. Rocker Arm, Fuel Injector | 5. Cylinder Head |

3. Camshaft Cap | 6. Rocker Arm, Intake Valve |

Figure 9. Cylinder Head Lubrication Schematic

Section 1.28.1

Repair or Replacement of Camshaft and Camshaft Bearing

To determine if repair or replacement of the camshaft and camshaft bearings is necessary, perform the following procedure. See Figure 'Flowchart for Repair or Replacement of Camshaft and Related Parts' .

Figure 10. Flowchart for Repair or Replacement of Camshaft and Related Parts

Section 1.28.2

Removal of Camshaft and Camshaft Bearing

Removal of camshaft and camshaft bearings as follows:

- Remove the valve rocker cover. Refer to '1.6.2 Removal and Cleaning of One-piece Rocker Cover For Diesel Engines Only' (one-piece), refer to '1.6.3 Removal and Cleaning of Two-piece Rocker Cover For Diesel Engines Only' (two-piece), refer to '1.6.5 Removal and Cleaning of Three-piece Rocker Cover' (three-piece).

- Remove the five bolts that secure the camshaft drive gear access cover to the gear case. See Figure 'Camshaft Drive Gear Access Cover and Adjustable Idler Gear Access' .

- Remove both rocker arm shaft assemblies. Refer to '1.3.2 Removal of Rocker Arm Assembly' .

NOTICE:

Only retaining tool (J–35652–B) , should be used to hold the camshaft drive gear stationary while loosening or tightening the camshaft drive gear-to-camshaft bolt. Other tools or devices can cause engine damage.

- Insert the shoe of the camshaft drive gear torque retaining tool (J–35652–B) through a lightening hole of the camshaft drive gear.

- Bar the engine over slightly to position the camshaft drive gear holding tool so that the bolt holes in the holding tool align with the access cover bolt holes in the gear case cover, using the 3/4 in. square hole in the center of the crankshaft pulley.

- Install retaining tool (J–35652–B) to the gear case, engaging one of the lightening holes in the camshaft drive gear. Use two of the access cover bolts to secure the tool to the gear case. See Figure 'Camshaft Drive Gear Torque Holding Tool Installation' .

Figure 11. Camshaft Drive Gear Torque Holding Tool Installation

- Use a long 3/4 in. drive breaker bar and a 27 mm impact socket to remove the camshaft drive gear-to-camshaft bolt.

- Remove the camshaft drive gear torque holding tool from the gear case.

- Rotate the crankshaft, using the square hole in the middle of the crankshaft pulley, to align the lightening holes in the camshaft drive gear to the camshaft thrust plate mounting bolts.

- Remove the camshaft thrust plate mounting bolts carefully, to avoid dropping them into the gear case. The current plate uses three bolts, the former plate requires two bolts. See Figure 'Camshaft Thrust Plate Mounting Bolt Locations' .

Note: A clean shop towel may be inserted into the gear case opening to trap the bolts in case they are dropped. Do not allow the shop towel to drop into the gear case.

1. Camshaft Thrust Plate Mounting Bolt Locations

Figure 12. Camshaft Thrust Plate Mounting Bolt Locations

- Install pilot tool (J–35906) to the camshaft drive gear access opening using three of the access cover bolt holes. Engage the puller screw in the threads of the camshaft drive gear hub, until the screw is tight. See Figure 'Camshaft Thrust Plate Remover' .

Figure 13. Camshaft Thrust Plate Remover

- Continue turning the puller screw to pull the camshaft drive gear hub and thrust plate forward approximately 6-7 mm (1/4 in.) until the thrust plate seal is clear of the camshaft front bearing cap and cylinder head. See Figure 'Camshaft Thrust Plate Clearance' .

Figure 14. Camshaft Thrust Plate Clearance

- Remove the three bolts that secure the rear camshaft cover to the engine and remove the cover.

- Remove the remaining seven camshaft cap bolts. Remove the No. 1 and 7 studs using socket tool (J–44706) . See Figure 'Camshaft Cap Stud Removal' .

Figure 15. Camshaft Cap Stud Removal

- Remove the seven camshaft bearing caps and the upper bearing shells. Keep the caps and shells together for possible later installation. Tag the bearing cap location, as they must always be installed in the same location.

- The camshaft gear pilot tool will remain in place, holding the camshaft drive gear in contact with the adjustable idler gear, to prevent accidental disengagement. This arrangement makes it unnecessary to re-time the gear train.

Note: The camshaft gear can go out of time if the pilot tool is removed.

- Slide the camshaft rearward to completely disengage the dowel from the hub. Lift out the camshaft.

- Remove the lower camshaft bearing shells, and group them with the upper shells and caps for possible reuse.

Section 1.28.3

Disassembly of Camshaft and Camshaft Bearing

Refer to '1.29.2 Removal of Camshaft Drive Gear' for disassembly of camshaft drive gear, camshaft hub and thrust plate assembly.

Note: Disassembly of camshaft and drive gear assembly is not required for inspection. Disassembly will require timing of the camshaft gear again.

For Series 60 engines equipped with Compact Gear Train Assembly disassemble camshaft from the camshaft gear as follows.

- Use suitable fixture to secure the camshaft assembly from movement.

- Install a heavy duty gear puller capable of withstanding the 48260 kPa (7000 psi) required to remove the gear from the camshaft. Support the backside of the camshaft gear cover as close to the camshaft as possible to prevent damaging the gear cover and gently press the camshaft off the gear holding the camshaft as it is pressed through the gear. Removing the camshaft gear and cover together.

NOTICE

Extreme care must be taken not to support the camshaft gear cover at the outer edges.

Section 1.28.3.1

Inspection of Camshaft and Camshaft Bearing

Inspect camshaft and camshaft bearings as follows:

- Clean all of the removed parts in clean fuel oil.

- Ensure all oil passages are clear.

EYE INJURY

To avoid injury from flying debris when using compressed air, wear adequate eye protection (face shield or safety goggles) and do not exceed 276 kPa (40 psi) air pressure.

- Dry with compressed air.

- Inspect the rocker arm components for scoring. Refer to '1.3.2.2 Inspection of Rocker Arm Assemblies and Camshaft Lobes' .

- Replace damaged rocker arm components.

- Inspect the camshaft lobes and journals for scoring, pitting, or flat spots.

Note: Camshafts may exhibit surface pits on the exhaust lobes. See Figure 'Camshafts Acceptable for Reuse' . Extensive durability and field testing has shown that surface pits on the exhaust lobes can occur early in the operation of the engine. These blemishes do not adversely affect engine performance or the durability of the camshaft and followers. Camshafts with this condition may be reused.

Figure 16. Camshafts Acceptable for Reuse

Note: Camshafts exhibiting extensive wear and pitting must be replaced. See Figure 'Camshafts Not Acceptable for Reuse' .

Figure 17. Camshafts Not Acceptable for Reuse

- If the camshaft is scored, inspect the camshaft follower rollers.

- Replace damaged camshaft followers.

- If there is a doubt as to the acceptability of the camshaft for further service, determine the extent of camshaft lobe wear as follows:

Note: The camshaft can be in or out of the engine during this procedure.

- Using a feeler gage, 0.038-0.254 mm (0.0015 -0.010 in.) and a piece of square, hard material 3 x 10 x 25 mm (1/8 in. x 3/8 in. x 1 in.), measure the flat on the injector rise side of the camshaft lobes and nose of valve lobes. See Figure 'Checking Camshaft Lobe Wear' .

- If the flats measure greater than 0.076 mm (0.003 in.) in depth and there are no other camshaft defects, replace the camshaft.

- Inspect the camshaft bearings for signs of excessive wear, scoring or pitting.

- Replace camshaft bearings as necessary.

- Check the camshaft bearing clearance using plastic gaging material under each upper shell.

- Allowable clearance is 0.09 - 0.166 mm (0.0035 -0.0065 in.) or a maximum of 0.191 mm (0.0075 in.) with used parts.

- Replace excessively worn or scored parts.

- After completing the camshaft bearing clearance measurements, remove the rocker arm shafts, bearing caps, camshaft, and camshaft bearings. Keep the caps and shells together for possible reuse.

- Clean all of the plastic gaging material from the bearing shells and camshaft journals if used parts are to be reused.

- Remove all of the Gasket Eliminator from both the cylinder head and camshaft caps. Refer to 'Cleaning' in the 'General Information' section at the beginning of this manual.

- Coat the No. 1 and 7 bearing shell inserts with clean engine oil and install them to their respective locations in the cylinder head and camshaft caps.

- Install the camshaft to its normal position in the bearing saddles. Install the No. 1 and 7 camshaft caps to the cylinder head.

- Install the No. 1 and 7 camshaft cap outboard bolts and inboard studs and torque, using socket tool (J–44706) to the studs to 126–146 N·m (93–108 lb·ft).

- Using a dial indicator with magnetic base, check the run-out of the camshaft at the No. 4 bearing journal. See Figure 'Camshaft Run-out Measurement' . If camshaft run-out exceeds 0.050 mm (0.002 in.), replace the camshaft

Figure 18. Checking Camshaft Lobe Wear

Note: If one camshaft bearing needs to be replaced, replace both of the camshaft bearing shells.

Note: Check camshaft bearing clearance with bearing shells, camshaft, bearing caps and rocker arm shafts (without rocker assemblies in place) installed, and cap bolts, studs and nuts tightened to specification.

Figure 19. Camshaft Run-out Measurement

Section 1.28.4

Assembly of Camshaft and Camshaft Bearing

Refer to '1.29.3 Installation of Camshaft Drive Gear' for assembly of camshaft drive gear, camshaft hub and thrust plate assembly.

Section 1.28.5

Installation of Camshaft and Camshaft Bearing

Install the camshaft and camshaft bearings as follows:

- Coat the lower camshaft bearing shells with clean engine lubricating oil, and install them to their original positions. Note the position of oil holes and locating tangs.

Note: If new bearings are to be installed, the upper and lower shells MUST be replaced as a set.

EYE INJURY

To avoid injury from flying debris when using compressed air, wear adequate eye protection (face shield or safety goggles) and do not exceed 276 kPa (40 psi) air pressure.

- When installing a new camshaft, steam clean it to remove the rust preventive and blow dry with compressed air.

- Before installing the camshaft dowel into the camshaft hub, ensure that the dimple in the thrust plate is located at the 12 o'clock position to properly position bolt holes to cam cap and cylinder head. See Figure 'Indexing Camshaft Dowel' .

Figure 20. Indexing Camshaft Dowel

- Coat the lobes and journals of the camshaft with clean engine lubricating oil. Index the dowel pin in the camshaft with the dowel hole in the camshaft hub.

- Lower the camshaft into position and slide the camshaft forward, making certain that the camshaft dowel indexes with its mating hole in the camshaft thrust plate hub.

- Install the upper bearing shells to the No. 1, 4 and 7 camshaft caps, noting the position of the oil holes and locating tangs.

NOTICE:

Do not apply oil to the number 1 or number 7 camshaft bearing shells. These shells must be clean and dry for proper sealant application. Applying oil to the number 1 or number 7 shells may result in oil leakage from the camshaft bearing caps. NOTE: The camshaft will still have adequate clearance from the number 1 and number 7 shells due to the oil film thickness on bearings 2 through 6.

- Coat the number 2 through number 6 bearing shells with clean engine lubricating oil.

- For engines built after May 1999, a race track seal is used on the Number 1 bearing cap. For bearing cap Number 7, use one rubber O-ring in the counterbore in the cylinder head. Before assembling the camshaft cap to the cylinder head, ensure the O-ring is in place on the cylinder head.

- For engines built prior to May 1999, install the two rubber O-rings to the counterbores in the cylinder head at the Number 1 and 7 camshaft cap locations. Before assembling the camshaft caps to the cylinder head, ensure the two O-rings are in place on the cylinder head.

NOTICE:

For proper adhesion, assemble parts while RTV is wet. So not allow RTV to form a skin. Gasket Eliminator must be kept from the bearing shell sets and bearing surfaces. Gasket Eliminator cures with the absence of air. The length of time between installation of the Number 1 and 7 camshaft caps, and torquing the camshaft cap bolts and nuts should be kept to a minimum or improper lubrication will result causing engine damage.

- Clean and dry the camshaft bearing cap joint face surfaces as well as the portions of the cylinder head face that mate with. These areas must be clean and dry for proper sealant adhesion. Use LPS®, Permatex®, or an equivalent non-filming degreaser.

- Apply a continuous 1.6 mm (1/16 in.) bead of DDC gasket eliminator part number 23523064, or equivalent, to the joint face surfaces of the No. 1 and 7 camshaft caps. The bead must extend to the front edge of both caps. See Figure 'Gasket Eliminator Application' .

Figure 21. Gasket Eliminator Application

- Install the No. 1, 4 and 7 camshaft caps, with bearing shells in place, to their respective locations.

- Install and tighten the two inboard studs and outboard bolts on bearing caps No. 1 and 7 using socket tool (J–44706) , torque to 126–146 N·m (93–108 lb·ft).

- Install the No. 4 bearing cap outboard bolt and torque it to 126-146 N·m (93-108 lb·ft).

- Remove the three bolts holding the camshaft gear pilot tool(J–35906) to the gear case. Remove the camshaft gear pilot.

- Working through the camshaft drive gear access hole in the front of the gear case, tap the center of the camshaft drive gear with a fiber mallet or plastic hammer to move the camshaft thrust plate, hub and camshaft drive gear rearward in the gear case until the camshaft thrust plate bolts can be started in the cylinder head and No. 1 camshaft cap.

NOTICE:

Use care to ensure that the camshaft dowel is not disengaged during this step or damage to engine may result.

NOTICE:

Use care to prevent dropping thrust plate mounting bolts into the gear case. If not removed, fasteners dropped into the gear case may cause severe engine damage during start-up.

- Install the thrust plate mounting bolts through the thrust plate and into the cylinder head and No. 1 camshaft cap. Using a 13 mm socket and ratchet, tighten the bolts alternately and progressively to draw the thrust plate straight into the gear case. Torque the bolts to 30-38 N·m (22-28 lb·ft).

- Coat the threads and underside of the head of the camshaft drive gear-to-camshaft bolt with International Compound #2 (or equivalent). Install the bolt to the camshaft, finger-tighten.

Note: The camshaft should be held in place while starting the camshaft drive gear-to-camshaft bolt, to prevent disengaging the camshaft dowel from the thrust plate hub and requiring disassembly and timing of camshaft.

NOTICE:

Only retaining tool (J–35652–B) should be used to hold the camshaft drive gear stationary while loosening or tightening the camshaft drive gear-to-camshaft bolt to prevent component damage.

- Insert retaining tool (J–35652–B) through a lightening hole of the camshaft drive gear.

- Bar the engine over slightly to position the camshaft drive gear holding tool so that the bolt holes in the holding tool align with the access cover bolt holes in the gear case cover using the 3/4 in. square hole in the center of the crankshaft pulley to bar the engine over.

- Install two of the access cover bolts to secure the tool to the gear case.

- Torque bolt to 75 N·m (55 lb·ft).

- Turn bolt an additional 120 degrees. See Figure 'Torque Turn Limits' .

Figure 22. Torque Turn Limits

- Remove the camshaft drive gear torque retaining tool (J–35652–B) .

- Adjust the camshaft drive gear-to-adjustable idler gear lash. Refer to '1.24.2.1 Check Engine Timing' .

Note: Correct camshaft drive gear lash adjustment depends on the bolt and stud for No. 1 and 7 camshaft caps, the outboard bolt on No. 4 camshaft cap, and the camshaft drive gear-to-camshaft retaining bolt being tightened to the specified torque. However, the valve and injector spring pressures will not allow correct camshaft rotation. Therefore, do NOT install the rocker arm shaft assemblies before the camshaft gear lash has been measured and adjusted.

Section 1.28.5.1

Test of Camshaft End Play

Measure the camshaft end play, using a dial indicator and magnetic base, as follows:

- Install the dial indicator so that the pointer is in contact with either the camshaft drive gear-to-camshaft retaining bolt, or at the rear end of the engine, in contact with the end of the camshaft. See Figure 'Camshaft End Play' .

Figure 23. Camshaft End Play

- Grasp the camshaft between the No. 1 and 4 camshaft caps, and move the cam as far forward as possible. Zero the dial indicator.

- Move the camshaft as far as possible, to the rear. Read and record the total amount of end play as indicated.

- Allowable camshaft end thrust specifications are 0.076 - 0.381 mm (0.003 -0.015 in.) and are listed in Table 'Camshaft' .

- If the end play is beyond the maximum limit, loosen and re-torque the camshaft drive gear-to-camshaft retaining bolt, and the camshaft thrust plate retaining bolts, to ensure that the camshaft thrust plate is seated properly in the gear case.

- If the end play is still beyond the maximum limit, remove and replace the camshaft thrust plate. Refer to '1.28.2 Removal of Camshaft and Camshaft Bearing' for removal and refer to '1.28.3 Disassembly of Camshaft and Camshaft Bearing' for installation.

Section 1.28.6

Installation of Camshaft and Camshaft Bearing

Continue installing camshaft and camshaft bearings as follows:

- Install the bearing shells to the remaining No. 2, 3, 5, and 6 camshaft caps, noting the oil holes and locating tangs.

- Coat the bearing shells with clean engine lubricating oil.

- Install the remaining camshaft caps to their saddles on the cylinder head. Install the four outboard camshaft cap bolts for caps No. 2, 3, 5, and No. 6 finger-tight.

- Coat the rocker arm assemblies and camshaft liberally with clean engine lubricating oil.

- Install the rocker arm shaft assemblies to the cylinder head. Refer to '1.3.3 Installation of Rocker Arm Shaft Assembly' .

- Install the remaining inboard camshaft cap bolts and spacers through the rocker arm shafts and into No. 2, 3, 4, 5, and 6 camshaft caps. Install the two nuts and spacers to the studs at No. 1 and 7 camshaft caps.

- Torque the 11 bolts and two nuts to 126-146 N·m (93-108 lb·ft) using the sequence. See Figure 'Camshaft Cap Bolts and Rocker Arm Shaft Nut Torque Sequence' .

Note: It is not necessary to tighten bolts 9, 13, and 14 if a Jake Brake is to be installed.

Note: Jake Brakes are not on a natural gas engine.

Figure 24. Camshaft Cap Bolts and Rocker Arm Shaft Nut Torque Sequence

- Clean all old gasket material from the mating surfaces of the rear camshaft cover and the cylinder head. Refer to 'General Information' General Information.

- Apply a thin 1.5 mm (1/16 in.) bead of Gasket Eliminator, PT-7276 (Loctite® 518) or equivalent to the mating surface of the cover.

- Install the cover and torque the three bolts to 30-38 N·m (22-28 lb·ft).

- Clean all old gasket material from the mating faces of the camshaft drive gear access cover and the gear case cover.

- Insert a new gasket between the camshaft drive gear access cover and the gear case.

- Torque the bolts to 30-38 N·m (22-28 lb·ft), using the tightening sequence. See Figure 'Camshaft Drive Gear Access Cover Torque Sequences' .

Figure 25. Camshaft Drive Gear Access Cover Torque Sequences

- Adjust the intake and exhaust valve clearances and set the injector heights. Refer to '13.2 Valve Lash, Injector Height (Timing) and Jake Brake® Lash Adjustments' .

- Install the fan hub, fan, (refer to '4.6.6 Installation of the Engine Cooling Fan' ), and drive belts; refer to '14.6.9 Drive Belts' .

- Install any other components that were removed for this procedure.

Section 1.28.6.1

Testing of Camshaft Timing for Diesel Engines

Check the camshaft timing as follows:

NOTICE: |

The camshaft must be in time with the crankshaft. An engine which is 'out of time' may result in pre-ignition, uneven running or a loss of power. |

- Remove the valve cover. Refer to '1.6.2 Removal and Cleaning of One-piece Rocker Cover For Diesel Engines Only' for one-piece rocker cover. Refer to '1.6.3 Removal and Cleaning of Two-piece Rocker Cover For Diesel Engines Only' for two-piece rocker cover. Refer to '1.6.5 Removal and Cleaning of Three-piece Rocker Cover' for three-piece rocker cover.

- Select any cylinder for the timing check.

- Remove the rocker arm assembly for the cylinder selected. Refer to '1.3.2 Removal of Rocker Arm Assembly' .

- Remove the injector for that cylinder. Refer to '2.3.2 Removal of N2 Electronic Unit Injector' .

- Carefully slide a rod, approximately 304.8 mm (12 in.) long, through the injector tube hole until the end of the rod rests on top of the piston.

- Using the 3/4 in. square drive hole in the center of the crankshaft pulley and a 3/4 in. drive breaker bar, turn the crankshaft slowly in the direction of engine rotation. See Figure 'Barring Engine Over' . Stop when the rod reaches the end of its upward travel.

Figure 26. Barring Engine Over

Note: The cylinder selected must be on the compression stroke when performing this check.

- Remove the rod and turn the crankshaft, opposite the direction of rotation, between 1/16 and 1/8 of a turn.

- Select a dial indicator with 0.0254 mm (0.001 in.) graduations and a spindle movement of at least 25.4 mm (1 in.). Provide an extension for the indicator spindle. The extension must be long enough to contact the piston just before it reaches the end of its upward stroke.

- Install a magnetic dial indicator base in a suitable place on the cylinder head and position the dial indicator over the injector hole tube.

- Attach a suitable pointer to the gear case cover. The outer end of the pointer should extend over the vibration damper.

- Turn the crankshaft slowly in the direction of engine rotation until the indicator hand just stops moving. Continue turning the crankshaft until the indicator hand starts to move again.

- Reset the dial to zero.

- Turn the crankshaft until the indicator reading is 0.254 mm (0.010 in.).

- Scribe a line on the vibration damper in line with the end of the pointer.

- Slowly turn the crankshaft opposite the direction of engine rotation until the indicator hand just stops moving. Continue turning the crankshaft until the indicator hand starts to move again.

- Reset the dial to zero. Then turn the crankshaft in the same direction until the indicator reading is 0.254 mm (0.010 in.).

- Scribe a second line on the vibration damper in line with the end of the pointer.

- Scribe a third line half way between the first two lines. This is top dead center for the cylinder selected when the pointer is lined up with it.

- Remove the dial indicator and base from the engine.

- Install the injector that was removed. Refer to '2.3.5 Installation of the N2 Electronic Unit Injector' .

- Install the rocker arm assemblies. Refer to '1.3.3 Installation of Rocker Arm Shaft Assembly' .

- Turn the crankshaft opposite the direction of engine rotation while watching the injector rocker arm cam follower for the cylinder selected. Turn the crankshaft until the cam follower is on the base circle of the injector lobe of the cam.

- Install a magnetic dial indicator base on the cylinder head. Install a dial indicator so that the spindle rests directly on the injector cam follower roller for the cylinder selected.

Note: The spindle should be on the center line of the injector cam follower roller pin in order to get an accurate measurement of cam lift.

- Turn the crankshaft slowly, in the direction of engine rotation, until the center mark on the vibration damper lines up with the pointer.

- Check the dial indicator reading and compare the reading with the values listed in Table 'Camshaft Timing Setting Dimensions' to determine the correct indicator reading.

Engine

DDEC Version

Model

Camshaft Part No.

Model Year

Low Injector Cam Roller Lift at TDC

High Injector Cam Roller Lift at TDC

12.7 L

III

GK

23521680

1998

5.36 mm (0.211 in.)

6.76 mm (0.266 in.)

12.7 L

IV

PK, TK

23521680

1998

5.36 mm (0.211 in.)

6.76 mm (0.266 in.)

11.1 L

IV

EK

23522199

1998

5.46 mm (0.215 in.)

6.71 mm (0.264 in.)

11.1 L

III

SK

23518717

1993-1997

4.95 mm (0.195 in.)

6.53 mm (0.257 in.)

12.7 L

III

GK

23513565

1993-1997

4.95 mm (0.195 in.)

6.53 mm (0.257 in.)

11.1 L

III

WK

23513563

1993-1997

4.95 mm (0.195 in.)

6.53 mm (0.257 in.)

11.1 L

II

WU

8929484

1986-1993

4.39 mm (0.173 in.)

5.46 mm (0.215 in.)

12.7 L

II

GU

23505194

1986-1993

4.39 mm (0.173 in.)

5.46 mm (0.215 in.)

11.1 L

IV

LK

23524655

1999

5.21 mm (0.205 in.)

6.27 mm (0.247 in.)

11.1 L

IV

LK

23524914

1999

5.21 mm (0.205 in.)

6.27 mm (0.247 in.)

12.7 L

IV

BK, MK

23524292

1999

5.03 mm (0.198 in.)

6.10 mm (0.240 in.)

12.7 L

IV

MK, BK

23524912

1999-2000

5.03 mm (0.198 in.)

6.10 mm (0.240 in.)

12.7 L

IV

MK, BK

23528309

2000-2001

6.527 mm (0.257 in.)

7.594 mm (0.299 in.)

12.7 L

IV

MK

23528606

2001

5.893 mm (0.232 in.)

6.960 mm (0274 in.)

14 L

IV

HK

23524912

1999-2000

5.03 mm (0.198 in.)

6.10 mm (0.240 in.)

14 L

IV

HK

23528309

2000-2001

6.527 mm (0.257 in.)

7.594 mm (0.299 in.)

12.7 L

IV

MK_E

23531130

2002-2003

6.452 mm (0.254 in.)

7.214 mm (0.284 in.)

14L

IV

HK_E

23531130

2002-2003

6.452 mm (0.254 in.)

7.214 mm (0.284 in.)

12.7 L

V

MV_E

23532935

2004

6.655 mm (0.262 in.)

7.214 mm (0.284 in.)

14L

V

HV_E

23532935

2004

6.655 mm (0.262 in.)

7.214 mm (0.284 in.)

Table 17. Camshaft Timing Setting Dimensions - If the camshaft lift is incorrect, re-time the engine. Refer to '1.24.2.1 Check Engine Timing' .

- Refer to '12.7 Engine Run-in Instructions' for verification of proper camshaft and camshaft bearing installation.

Section 1.28.6.2

Testing of Camshaft Timing for Natural Gas Engines

Detroit Diesel Series 60 Jake Brake Torque Specs 2017

Check the camshaft timing as follows:

NOTICE: |

The camshaft must be in time with the crankshaft. An engine which is 'out of time' may result in pre-ignition, uneven running or a loss of power. |

- Remove the valve cover. Refer to '1.6.2 Removal and Cleaning of One-piece Rocker Cover For Diesel Engines Only' for one-piece rocker cover. Refer to '1.6.3 Removal and Cleaning of Two-piece Rocker Cover For Diesel Engines Only' for two-piece rocker cover. Refer to '1.6.5 Removal and Cleaning of Three-piece Rocker Cover' for three-piece rocker cover.

- Select any cylinder for the timing check.

- Remove the rocker arm assembly for the cylinder selected. Refer to '1.3.2 Removal of Rocker Arm Assembly' .

- Remove the spark plug for that cylinder.

- Carefully slide a rod, approximately 304.8 mm (12 in.) long, through the spark plug hole until the end of the rod rests on top of the piston.

- Using the 3/4 in. square drive hole in the center of the crankshaft pulley and a 3/4 in. drive breaker bar, turn the crankshaft slowly in the direction of engine rotation. See Figure 'Barring Engine Over' . Stop when the rod reaches the end of its upward travel.

Figure 27. Barring Engine Over

Note: The cylinder selected must be on the compression stroke when performing this check.

- Remove the rod and turn the crankshaft, opposite the direction of rotation, between 1/16 and 1/8 of a turn.

- Select a dial indicator with 0.0254 mm (0.001 in.) graduations and a spindle movement of at least 25.4 mm (1 in.). Provide an extension for the indicator spindle. The extension must be long enough to contact the piston just before it reaches the end of its upward stroke.

- Install a magnetic dial indicator base in a suitable place on the cylinder head and position the dial indicator over the spark plug hole.

- Attach a suitable pointer to the gear case cover. The outer end of the pointer should extend over the vibration damper.

- Turn the crankshaft slowly in the direction of engine rotation until the indicator hand just stops moving. Continue turning the crankshaft until the indicator hand starts to move again.

- Reset the dial to zero.

- Turn the crankshaft until the indicator reading is 0.254 mm (0.010 in.).

- Scribe a line on the vibration damper in line with the end of the pointer.

- Slowly turn the crankshaft opposite the direction of engine rotation until the indicator hand just stops moving. Continue turning the crankshaft until the indicator hand starts to move again.

- Reset the dial to zero. Then turn the crankshaft in the same direction until the indicator reading is 0.254 mm (0.010 in.).

- Scribe a second line on the vibration damper in line with the end of the pointer.

- Scribe a third line half way between the first two lines. This is top dead center for the cylinder selected when the pointer is lined up with it.

- Remove the dial indicator and base from the engine.

- Install the spark plug that was removed.

- Install the rocker arm assemblies. Refer to '1.3.3 Installation of Rocker Arm Shaft Assembly' .

- Turn the crankshaft opposite the direction of engine rotation while watching the intake rocker arm cam follower for the cylinder selected. Turn the crankshaft until the cam follower is on the base circle of that intake lobe of the cam.

- Install a magnetic dial indicator base on the cylinder head. Install a dial indicator so that the spindle rests directly on the intake cam follower roller for the cylinder selected.

Note: The spindle should be on the center line of the intake cam follower roller pin in order to get an accurate measurement of cam lift.

- Turn the crankshaft slowly, in the direction of engine rotation, until the center mark on the vibration damper lines up with the pointer.

- Check the dial indicator reading:

- The dial indicator reading for gas engines is 6.47 mm-7.54 mm (0.255 in. -0.297 in.).

- If the camshaft lift is incorrect, re-time the engine. Refer to '1.24.2.1 Check Engine Timing' .

- Refer to '12.7 Engine Run-in Instructions' for verification of proper camshaft and camshaft bearing installation.

| Generated on 10-13-2008 |

Section 1.36

Jake Brake

The engine brake has been designed to fit on the Series 60 engine with no additional valve cover spacers. There are three styles of valve covers for the Series 60 engine. On engines equipped with a two-piece aluminum valve cover, it is NOT necessary to remove the lower valve cover to install the engine brake. However, one style of upper valve cover may require modification at the breather housing location (inside) for engine brake clearance.

The model, part number and serial number are located on the nameplates at the top of each housing. See Figure 'Nameplate Location on Housing' .

1. Identification Plate |

Figure 1. Nameplate Location on Housing

NOTICE: |

Only the specific brake model can be used with the engine model it was designed for. Also, the correct slave piston adjustment specification must be used. Failure to follow these instructions may result in serious engine or engine brake damage. |

Listed in Table 'Jake Brake Model Information' are the different Jake Brake models used and the slave piston adjustment specification.

Model Number | Model Year | Engine Displacement | Engine Brake | Slave Piston Adjustment |

6067WU40 | Pre-1991 | 11.1L | 760/760A | 0.660 mm (0.026 in.) |

6067GU40 | Pre-1991 | 12.7L | 760/760A | 0.508 mm (0.020 in.) |

6067WU60 | 1991 | 11.1L | 760/760A | 0.660 mm (0.026 in.) |

6067GU40 | 1991 | 12.7L | 765 | 0.660 mm (0.026 in.) |

6067GU28 | 1991 | 12.7L | 765 | 0.660 mm (0.026 in.) |

6067GU91 | 1991 | 12.7L | 765 | 0.660 mm (0.026 in.) |

6067WK60 | 1994 | 11.1L | 760A | 0.660 mm (0.026 in.) |

6067GK60 | 1994 | 12.7L | 765 | 0.660 mm (0.026 in.) |

6067GK28 | 1994 | 12.7L | 765 | 0.660 mm (0.026 in.) |

6067EK60 | 1998 | 11.1L | 760B | 0.584 mm (0.023 in.) |

6067PK60 | 1998 | 12.7L | 765A | 0.584 mm (0.023 in.) |

6067TK60 | 1998 | 12.7L | 765A | 0.584 mm (0.023 in.) |

6067TK45 | 1998 | 12.7L | 765A | 0.584 mm (0.023 in.) |

6067MK60 | 1998 | 12.7L | 770 | 0.584 mm (0.023 in.) |

6067BK60 | 1998 | 12.7L | 770 | 0.584 mm (0.023 in.) |

6067HKXX | 1998 (Non-Line Haul) | 14L | 770 | 0.584 mm (0.023 in.) |

6067MK28, 6067MK45, 6067MK57, 6067MK60 | 2000 | 12.7L Standard | 790 | 0.660 mm (0.026 in.) |

6067BK28, 6067BK45, 6067BK57, 6067BK60 | 2000 | 12.7L Premium | 790 | 0.660 mm (0.026 in.) |

6067HK45, 6067HK60 | 2000 | Vienna symphonic library crack minecraft. 14L U.S. | 790A | 0.660 mm (0.026 in.) |

6067WK28, 6067WK60 | 2000 | 11.1L | 790B | 0.660 mm (0.026 in.) |

6067LK28, 6067LK45, 6067LK60 | 2000 | 11.1L | 790B | 0.660 mm (0.026 in.) |

6067GK28, 6067GK45, 6067GK91, 6067PK62, 6067TK28, 6067TK60, 6067TK62 | 2000 | 12.7L | 790B | 0.660 mm (0.026 in.) |

6067HK62 | 2000 | 14L Australian | 790C | 0.660 mm (0.026 in.) |

6067MK28, 6067MK45, 6067MK57, 6067MK60 | 2000 | 12.7L Standard | 795 | 0.813 mm (0.032 in.) |

6067BK28, 6067BK45, 6067BK57, 6067BK60 | 2000 | 12.7L Premium | 795 | 0.813 mm (0.032 in.) |

6067HK45, 6067HK60 | 2000 | 14L U.S. | 795 | 0.813 mm (0.032 in.) |

6067WK28, 6067WK60 | 2000 | 11.1L | 795 | 0.813 mm (0.032 in.) |

6067LK28, 6067LK45, 6067LK60 | 2000 | 11.1L | 795 | 0.813 mm (0.032 in.) |

6063GK60, 6067GK28, 6067GK45, 6067GK91, 6067PK62, 6067TK28, 6067TK60, 6067TK62 | 2000 | 12.7L | 795 | 0.813 mm (0.032 in.) |

6067HK62 | 2000 | 14L Australian | 795 | 0.813 mm (0.032 in.) |

All slave piston adjustments shown here are current as of the date of this manual and supersede all previous adjustments.

XXXX = Model numbers to be determined.

Note: All engines built after serial number 06R0004455 have the correct engine parts for engine brake installation. The model numbers have changed because of design changes in the engine brakes.

Note: All Series 60 engines with serial numbers 06R0004455 or higher are Jake Brake ready. Do not install a Jake Brake on engines with lower serial numbers.

Effective August 10, 2000, Model 795 Jake Brakes are used on all Series 60 engines requiring an engine brake.

Former Jake Brake production models for the Series 60 engine were the 760A (which replaced model 760), 760B, 765, 765A, 770 and 790.

Detroit Diesel engine model Nos. 6067GU28 and 6067GK28 are for bus/coach applications. Due to interference fits on some coach chassis, a two-housing Jake Brake kit may be required. Contact your Detroit Diesel Distributor for information on these kits.

Jake Brake® is a registered trademark of Jacobs Vehicle Systems. J-Lash™ is a trademark of Jacobs Vehicle Systems.

Energizing the engine brake effectively converts a power-producing diesel engine into a power-absorbing air compressor. This is accomplished through motion transfer using a master-slave piston arrangement which opens cylinder exhaust valves near the top of the normal compression stroke, releasing the compressed cylinder charge to exhaust. See Figure 'Jake Brake Schematic' .

1. Exhaust Valve | 7. Oil In |

2. Slave Piston Assembly | 8. Check Valve (Model 760) |

3. Exhaust Valve | 9. Solenoid Valve |

4. Leveling Screw | 10. Control Valve |

5. Slave Piston Adjusting Screw | 11. Master Piston |

6. Accumulator | 12. Injector Pin and Roller |

Figure 2. Jake Brake Schematic

The blowdown of compressed air to atmospheric pressure prevents the return of energy to the engine piston on the expansion stroke, the effect being a net energy loss, since the work done in compressing the cylinder charge is not returned during the expansion process.

Exhaust blowdown occurs as the energized solenoid valve permits engine lube oil to flow under pressure through the control valve to both the master piston and the slave piston. See Figure 'Jake Brake Schematic' .

Oil pressure causes the master piston to move down, coming to rest on the injector rocker arm roller.

The injector rocker arm begins its travel as in the normal injection cycle, moving the master piston upward and directing high-pressure oil to the slave piston. The ball check valve in the control valve traps high-pressure oil in the master-slave piston system.

High pressure oil causes the slave piston to move down, momentarily opening the exhaust valves, while the engine piston is near its top-dead-center position, releasing compressed cylinder air to the exhaust manifold.

At the bottom of its stroke, the slave piston separates from the valve in the slave piston adjusting screw, allowing high pressure oil to flow into the accumulator. This reduces the pressure in the high pressure circuit, permitting the slave piston to retract and the exhaust valves to close in preparation for the normal exhaust valve cycle. The oil pressure reserved in the accumulator ensures that the hydraulic circuit is fully charged for the next cycle. Compressed air escapes to the atmosphere, completing a compression braking cycle.

The Jake Brake is electronically controlled. Jake Brake control system wiring will vary depending on the vehicle manufacturer. For a general overview of the Jake Brake, see Figure 'Typical Model 760, 765, or 770 Jake Brake Assembly' and see Figure 'Typical Model 790/795 Jake Brake Assembly' .

1. Ball Check Valve (Model 760 Only) | 8. Control Valve Spring | 15. Power Lash Assembly |

2. Washer | 9. Collar Spring | 16. Slave Piston Adjusting Screw |

3. Master Piston | 10. Washer | 17. Slave Piston |

4. Master Piston Spring | 11. Snap Ring Retainer | 18. Slave Piston Leveling Screw |

5. Washer and Screw Assembly | 12. Solenoid Valve | 19. Bridge |

6. Control Valve | 13. Seal Rings | 20. Return Spring |

7. Collar | 14. Accumulator Piston | 21. Screw |

Figure 3. Typical Model 760, 765, or 770 Jake Brake Assembly

1. Solenoid Valve | 9. Master Piston Retaining Ring | 17. Slave Piston |

2. Solenoid Upper Seal Ring | 10. Control Valve | 18. Slave Piston Bridge |

3. Solenoid Center Seal Ring | 11. Outer Control Valve Spring | 19. Outer Slave Piston Spring |

4. Solenoid Lower Seal Ring | 12. Inner Control Valve Spring | 20. Inner Slave Piston Spring |

5. Master Piston | 13. Control Valve Cover | 21. Spacer Tube |

6. Master Piston Pushrod | 14. Retaining Ring | 22. Shoulder Bolt |

7. Master Piston Spring | 15. Adjusting Screw* | 23. Drive Screw |

8. Master Piston Retainer | 16. Locknut | 24. Wire Harness Clip |

Detroit Diesel Series 60 Jake Brake Torque Specs List

*Note that Model 790 Jake Brake uses a J-Lash™ assembly. Model 795 Jake Brake uses a solid screw.Figure 4. Typical Model 790/795 Jake Brake Assembly

NOTICE: |

This application and adjustment information must be strictly followed. Failure to follow these instructions may result in serious engine or engine brake damage. |

Section 1.36.1

Repair or Replacement of Jake Brake®

To determine if repair is possible or replacement is necessary, perform the following procedure. See Figure 'Jake Brake® Repair or Replacement Flowchart' .

Figure 5. Jake Brake® Repair or Replacement Flowchart

Section 1.36.2

Removal of Model 760, 765, or 770 Jake Brake

Remove the model 760, 765, or 770 Jake Brake as follows:

Note: The following procedures apply to Model 760, 765, and 777 Jake Brake. For Model 790/795 Jake Brake removal procedures, refer to '1.36.6 Removal of Model 790/795 Jake Brake Assembly'.

PERSONAL INJURY |

To avoid injury, never remove any engine component while the engine is running. |

- Disconnect starting power for engine. Refer to OEM guidelines.

- Remove the engine rocker cover. Refer to '1.6.2 Removal and Cleaning of One-piece Rocker Cover For Diesel Engines Only' for one-piece, refer to '1.6.3 Removal and Cleaning of Two-piece Rocker Cover For Diesel Engines Only' for two-piece and refer to '1.6.5 Removal and Cleaning of Three-piece Rocker Cover' for three-piece.

Note: If the engine is equipped with an aluminum two-piece valve cover, remove only the upper valve cover when installing the engine brake.

- Note the location of the rocker arm shaft, the exhaust valve rocker arm, the fuel injector rocker arm, and the intake valve rocker arm.

- Disconnect the solenoid wiring harness connectors from the engine brake solenoids. See Figure 'Jake Brake Assembly' .

1. Cylinder Head

4. Washers (3 each)

2. Jake Brake Assembly

5. Capscrews (3 each)

3. Solenoid

6. Engine Brake Harness

Figure 6. Jake Brake Assembly

- Remove the nine capscrews and washers that secure the engine brake assemblies to the cylinder head. See Figure 'Jake Brake Assembly' .

Note: Only the Model 760 Jake Brake uses two different length capscrews. Six bolts, 120 mm (4.72 in.) long, are used on the exhaust side of the engine. Three bolts, 110 mm (4.33 in.) long, are used on the intake side of the engine. These bolts must be reinstalled in their correct positions.

- Remove the engine brake assemblies and the spacer bar.

Section 1.36.3

Disassembly of Model 760, 765, or 770 Jake Brake

Remove the control valve as follows:

EYE INJURY |

To avoid injury from flying parts when working with components under spring tension, wear adequate eye protection (face shield or safety goggles). |

- Press down on control valve washer using an appropriate diameter rod to relieve spring pressure. See Figure 'Relieving Spring Pressure' .

1. Jake Brake Assembly

3. Snap Ring Retainer

2. Spring

4. Snap Ring Pliers

Figure 7. Relieving Spring Pressure

- Using retaining ring pliers, remove retaining ring.

- Slowly remove cover until spring pressure ceases, then remove the two control valve springs and collar. See Figure 'Removing Control Valve Springs and Collar' .

1. Jake Brake Assembly

5. Washer

2. Control Valve

6. Collar Spring

3. Collar

7. Control Valve Spring

4. Snap Ring Retainer

Figure 8. Removing Control Valve Springs and Collar

- Using needle-nose pliers, reach into the bore and grasp the stem of the control valve. Remove control valve.

Remove the slave piston adjusting screw as follows:

- Loosen slave piston adjusting screw locknut.

- Remove adjusting screw from housing. See Figure 'Removing Slave Piston Adjusting Screw' .

1. Jake Brake Assembly

2. Slave Piston Adjusting Screw

Figure 9. Removing Slave Piston Adjusting Screw

Remove the solenoid valve as follows:

NOTICE: |

To avoid possible engine damage, do not disassemble or tamper with the solenoid valve. |

- Disconnect solenoid valve harness.

- Using a 7/8 in. socket and extension for former solenoids or a 3/4 in. 6 point socket and extension for current solenoids, unscrew solenoid valve.

- Remove and discard the three rubber seal rings. See Figure 'Removing Rubber Seal Rings' .

1. Seal Rings (3)

2. Solenoid

Figure 10. Removing Rubber Seal Rings

- If the lower ring stays in the bottom of the housing bore, remove with a piece of wire.

Remove the accumulator as follows:

EYE INJURY |

To avoid injury from flying parts when working with components under spring tension, wear adequate eye protection (face shield or safety goggles). |

- Push down on the accumulator cover using the appropriate diameter rod, and remove the retaining ring. See Figure 'Removing Retaining Ring' .

1. Jake Brake Assembly

3. Retaining Ring Pliers

2. Retaining Ring

Figure 11. Removing Retaining Ring

- Relieve pressure on the accumulator cover.

- Remove the cover and spring.

- Use a magnet to remove the piston from the accumulator bore. See Figure 'Removing Piston from Accumulator Bore with Magnet' .

1. Jake Brake Assembly

4. Retaining Ring

2. Piston

5. Washer

3. Spring

Figure 12. Removing Piston from Accumulator Bore with Magnet

Remove the master piston as follows:

- Remove the screw, washer, and master piston spring from the housing.

- Remove the master piston. See Figure 'Removing the Master Piston' .

Note: Use needle-nose pliers, if necessary.

1. Washer and Screw Assembly

3. Master Piston

2. Jake Brake Assembly

4. Master Piston Spring

Figure 13. Removing the Master Piston

On Model 760 only, remove the ball check valve as follows:

- Remove the plug.

- Remove the ball check valve and spring.

Remove the slave piston as follows:

- Remove the screw and washer that retains the slave piston return spring.

- Remove the bridge and the slave piston. See Figure 'Removing Bridge and Slave Piston' .

1. Slave Piston Bridge

4. Return Spring

2. Jake Brake Housing

5. Washer

3. Slave Piston

6. Screw

Figure 14. Removing Bridge and Slave Piston

- Loosen the leveling screw locknut and remove the leveling screw from the bridge. See Figure 'Removing the Leveling Screw from the Bridge' .

1. Slave Piston Bridge

2. Slave Piston Leveling Screw

Figure 15. Removing the Leveling Screw from the Bridge

The injector rocker arm contains a pin and roller for actuating the engine brake master piston. If excessive wear or damage to the roller is present, replace the rocker arm assembly. Refer to '1.6.2 Removal and Cleaning of One-piece Rocker Cover For Diesel Engines Only' .

Section 1.36.3.1

Cleaning of Model 760, 765, or 770 Jake Brake

Clean the Jake Brake as follows:

Note: Use an OSHA-approved cleaning solvent when washing parts. Be sure to coat parts with clean engine oil when reinstalling them.

- Wash the control valves with approved cleaning solvent.

- Push a wire through the hole in the base of the valve to the distance required to ensure that the ball check is free.

Note: The ball should lift with light pressure on the wire.

EYE INJURY

To avoid injury from flying debris when using compressed air, wear adequate eye protection (face shield or safety goggles) and do not exceed 276 kPa (40 psi) air pressure.

- Dry the valve with compressed air, and wipe clean with a paper towel.

- Thoroughly clean the control valve bore in the housing using clean paper towels.

- Clean slave piston adjusting screw in an approved cleaning solvent.

- Clean out the solenoid valve bore in the housing.

NOTICE:

Use clean paper towels to clean the solenoid valve bore. Never use rags, as they may leave lint and residue which can plug the oil passageways, causing Jake Brake malfunction.

- Clean the master piston in approved cleaning solvent.

Section 1.36.3.2

Inspection of Model 760, 765, or 770 Jake Brake

The Jacobs engine brake is typically a trouble-free device. However, inspections are necessary and some maintenance is required. Use the following procedures to keep the engine brake in top condition.

Inspect the Jake Brake as follows:

- Inspect slave piston adjusting screw for protrusion, spring pressure and freedom of movement.

Note: The plunger should protrude from the bottom of the screw, have light spring pressure apparent when depressed, and move freely. Be sure the retaining ring is fully engaged in its groove (groove is located on the bottom of the reset screw and top of the POWER-LASH assembly).

- If the plunger does not protrude, the spring does not have light pressure or does not move freely, replace the entire screw assembly. Refer to '1.36.4 Assembly of Model 760, 765, or 770 Jake Brake'

- If the slave piston adjusting screw meets specifications, continue with inspection.

- Inspect the accumulator for wear or damage.

- If worn or damaged, replace the accumulator. Refer to '1.36.4 Assembly of Model 760, 765, or 770 Jake Brake' .

- If accumulator is not worn or damaged, continue with inspection.

- Inspect the master piston bore for wear or damage.

Note: Some wear marks are permissible.

- If worn or damaged, replace the master piston. Refer to '1.36.4 Assembly of Model 760, 765, or 770 Jake Brake' .

- If not worn or damaged, continue with inspection.

- Apply clean lube oil to the piston, and insert into bore.

Note: Master piston should move in and out freely with no binding.

- If binding occurs, replace master piston and/or housing. Refer to '1.36.4 Assembly of Model 760, 765, or 770 Jake Brake' .

- If no binding occurs, continue with inspection.

- Inspect master piston spring for relaxation.

Note: The spring should hold the master piston completely in the housing.

- If relaxed, replace the spring. Refer to '1.36.4 Assembly of Model 760, 765, or 770 Jake Brake' .

- If spring holds tightly, continue with inspection.

- Inspect the ball check valve (Model 760 only) for wear or damage.

- If worn or damaged, replace ball check valve. Refer to '1.36.4 Assembly of Model 760, 765, or 770 Jake Brake' .

- If not worn or damaged, proceed with inspection.

- Inspect slave piston components for excessive wear or damage.

- If worn or damaged, replace slave piston component.

- If not worn or damaged, proceed with inspection.

Section 1.36.3.3

Inspection of Control Valve

Inspect the control valve as follows:

- Dip the control valves in clean lube oil.

- Holding the control valve by the stem, let it drop into the bore.

- If binding occurs or if the ball sticks in the valve, replace the control valve. Refer to '1.36.4 Assembly of Model 760, 765, or 770 Jake Brake' .

- If no binding occurs and the ball does not stick in the control valve, assemble the Jake Brake. Refer to '1.36.4 Assembly of Model 760, 765, or 770 Jake Brake' .

Section 1.36.4

Assembly of Model 760, 765, or 770 Jake Brake

Install the control valve as follows:

- Slip the control valve into the bore. See Figure 'Installing the Control Valve' .

Note: Make sure the control valve collar is installed with the longer sleeve area facing up. If the collar is installed upside down, the engine brake cylinder will not operate.

1. Jake Brake Assembly

5. Washer

2. Control Valve

6. Collar Spring

3. Collar

7. Control Valve Spring

4. Snap Ring Retainer

Figure 16. Installing the Control Valve

- Install the control valve collar and two springs.

Note: Ensure the collar is installed with the longer sleeve area facing up. If the collar is installed upside down, the engine brake cylinder will not operate.

- Press the cover (washer) into place.

- While holding the cover tightly in place, install the retaining ring.

- Rotate retaining ring ears 90 degrees to assure ring is seated in groove.

Install the slave piston adjusting screw as follows:

- Place the screw in the housing. See Figure 'Installing the Slave Piston Adjusting Screw' .

1. Jake Brake Assembly

2. Slave Piston Adjusting Screw

Figure 17. Installing the Slave Piston Adjusting Screw

- Torque the slave piston adjusting screw locknut to 35 N·m (25 lb·ft).

Install the solenoid valve as follows:

Note: As of October 19, 1997, former solenoids have been replaced with the current improved solenoids. The current solenoids have an increased installation torque and improved durability. The current solenoid is interchangeable with the former.

- Coat new solenoid valve seal rings with clean lube oil.

Note: Use current upper seals when installing current solenoids. New seals are identified with yellow stripes.

- Install the upper and center seal rings on the solenoid valve body and the lower seal ring into the bottom of the bore in the housing. See Figure 'Installation of Solenoid Valve Seal Rings' .

1. Seal Rings (3)

2. Solenoid

Figure 18. Installation of Solenoid Valve Seal Rings

- Make sure the seals are seated properly.

- Using a 7/8 in. socket and extension for former solenoids or a 3/4 in., 6 point socket and extension for current solenoids, carefully screw the solenoid valve into the housing without unseating the seals.

- Torque the former solenoid to 12.4 N·m (9 lb·ft). Torque the current solenoid to 20 N·m (15 lb·ft.)

Note: Be careful not to twist the seals while installing.

Install the accumulator as follows:

- Place the piston into the accumulator bore.

- Insert the spring, and install the cover.

- Push down the accumulator cover, and insert retaining ring.

Install the master piston as follows:

- Apply clean lube oil to the piston.

- Insert master piston into bore. See Figure 'Inserting Master Piston into Bore' .

1. Washer and Screw Assembly

3. Master Piston

2. Jake Brake Assembly

4. Master Piston Spring

Figure 19. Inserting Master Piston into Bore

- Install spring, washer, and screw.

Note: Make sure spring legs are centered around master piston boss.

- Torque screw to 10 N·m (7.4 lb·ft).

On model 760 only, install the ball check valve as follows:

- Install the ball check valve and spring. See Figure 'Installation of Ball Check Valve' .

1. Ball Check Valve

3. Pipe Plug

2. Spring

Figure 20. Installation of Ball Check Valve

- Insert the plug. Torque pipe plug to 11.2 N·m (8.3 lb·ft).

Install the slave piston as follows:

- Install the screw from the slave piston side of the bridge.

- Install the leveling screw locknut.

- Install the bridge with the leveling screw toward the center of the housing. See Figure 'Installing Bridge with Leveling Screw Toward Center of Housing' .

1. Washer

4. Bridge Assembly

2. Screw

5. Jake Brake Housing

3. Torsion Spring

Figure 21. Installing Bridge with Leveling Screw Toward Center of Housing

- Install the slave piston assembly torsion spring with the ends over the bridge. See Figure 'Installing the Slave Piston Assembly Torsion Spring' .

Figure 22. Installing the Slave Piston Assembly Torsion Spring

- Install the screw and washer over the center part of the spring.

NOTICE:

While tightening the screw on the torsion spring, push the spring toward the slave piston assembly. Failure to do so may result in contact between the intake valve adjusting screw and torsion spring. Serious engine damage may result.

- Torque the screw to 20 N·m (15 lb·ft.).

- Torque the slave piston leveling screw locknut to 47 N·m (35 lb·ft.).

Section 1.36.5

Installation of Model 760, 765, or 770 Jake Brake

Install the model 760, 765, or 770 Jake Brake as follows:

Detroit Diesel Series 60 Jake Brake Torque Specs 2004 Dodge Ram 1500

Note: The following procedures apply to Model 760, 765, and 770 Jake Brake. For Model 790/795 Jake Brake installation procedures, refer to '1.36.8 Installation of Model 790/795 Jake Brake Assembly'.

- Adjust the intake and exhaust valve clearances and set the injector heights. Refer to '13.2 Valve Lash, Injector Height (Timing) and Jake Brake® Lash Adjustments' .

EYE INJURY

To avoid injury from flying debris when using compressed air, wear adequate eye protection (face shield or safety goggles) and do not exceed 276 kPa (40 psi) air pressure.

- Attach the length of tubing to a blow gun nozzle, and blow out the oil from the bolt holes.

- Cover the holes with hand towels to minimize oil spray.

Note: Removing the oil from the bolt holes prevents the cylinder head from cracking when tightening the bolts.

- Place the spacer bar on the exhaust manifold side of the cylinder head with the 'OUT' markings adjoining each other and facing the exhaust manifold. See Figure 'Spacer Bars with 'Out' Marks Adjoined' , and see Figure 'Location of Spacer Bars' .

Figure 23. Spacer Bars with 'Out' Marks Adjoined

Figure 24. Location of Spacer Bars

- Place the three engine brake housings over the rocker shafts with the solenoid valves toward the camshaft side of the engine.

Note: Be sure housings do not interfere with wiring harness.

LOSS OF BRAKING Komik tintin bahasa indonesia lengkap.

To avoid injury from the loss of braking control due to an improperly installed engine brake, do not mix rocker arm shaft and engine brake mounting bolts.

NOTICE:

Do not mix the rocker arm shaft bolts and the Jake Brake capscrews. If the rocker arm shaft bolt is mistakenly used to mount the Jake Brake housing, the longer shoulder on the bolt will block the oil supply to the Jake Brake on the camshaft side of the housing. The brake will not retard the engine as designed. This condition could cause vehicle damage.

Note: The rocker arm shaft capscrew and Jake Brake capscrew, part of the Jake Brake assembly, are similar in appearance. Both are M12 x 110 mm (4.33 in.) long and have 12–point heads.

Note: In the event of a housing hold down bolt failure on a Jacobs engine brake housing, replace all bolts on that particular housing.

NOTICE:

Use bolts that have the Jacobs logo, circled 'J'. Installation of bolts that do not have the circled 'J' may result in damage to the engine, engine brake or both.

- The Jake Brake bolt has the Jacobs logo (circled 'J') and the letters 'EF' marked on the head. The bolt length is no longer marked atop the bolt head.

- The DDC rocker arm shaft bolt has the DDC logo (spinning arrows) and the vendor I.D. (F-C) on its head.

- Jake Brake model 760 requires two bolts along with one bolt and new washers.

- The DDC bolt shoulder is much longer, 17.0 mm (0.669 in.) versus 4 mm (0.157 in.) than the Jake Brake bolt. See Figure 'Jake Brake and DDC Bolt Identification' .

Note: Be sure that only Jake Brake bolts, see Figure 'Jake Brake and DDC Bolt Identification' , are installed in the Jake Brake housing.

Figure 25. Jake Brake and DDC Bolt Identification

NOTICE:

The model 760 uses two lengths of capscrews. Six 120 mm bolts should be installed on the exhaust side of the engine. Three 110 mm bolts should be installed on the camshaft side of the engine. Failure to do so will result in engine damage.

- On model 760, install one washer onto each 120 mm (4.72 in.) bolt, and insert into brake housing on the exhaust manifold side (two per housing). See Figure 'Installation of Jake Brake Housing Bolts on Exhaust Manifold Side' .

1. Washer

2. Long Bolt

Figure 26. Installation of Jake Brake Housing Bolts on Exhaust Manifold Side

- On model 760, install one washer on the 110 mm (4.331 in.) bolt, and insert into brake housing at the camshaft side (one per housing). See Figure 'Installation of Jake Brake Housing Bolts on Camshaft Side' .

1. Jake Brake Housing Assembly

2. Capscrew

Figure 27. Installation of Jake Brake Housing Bolts on Camshaft Side

- On models 760A, 760B, 765, and 765A, lubricate each hold down bolt with clean engine oil.

Note: All the housing capscrews for these models are the same length of 110 mm (4.331 in.).

- On models 760A, 760B, 765, and 765A, install a washer on each bolt, and install into housings (three bolts per housing).

- On models 760A and 765, move the housing from side to side, and locate the housing in the center position of the movement. See Figure 'Locating Center Position of Housing' .

Figure 28. Locating Center Position of Housing

- On models 760B and 765A, move the housing from side to side, and locate as far toward the camshaft side of the engine as possible.

- On all models, torque the engine brake capscrews using the following sequence:

- Torque the three bolts on the camshaft side of the engine to 55 N·m (40 lb·ft).

- Torque the six bolts on the exhaust manifold side of the engine to 55 N·m (40 lb·ft).

- Repeat the tightening sequence and re-torque all bolts to 136 N·m (100 lb·ft).

- Check the torque to 136 N·m (100 lb·ft).

- Secure injector wire harness to each of the six Jake Brake spacer bars with tie straps.

- Verify tie strap is properly seated on the spacer bar. See Figure 'Injector Harness Tie Strap Location'

- Verify tie strap is tight on spacer bar and does not move.

- Clip excess tails from tie strap.

Note: Ensure all wires are away from moving parts.

1. Injector Harness

2. Tie Strap

3. Spacer Bar

Figure 29. Injector Harness Tie Strap Location

- Connect wiring harness solenoid connectors to solenoids. See Figure 'Jake Brake Wire Terminal Connection Identification'